-

More

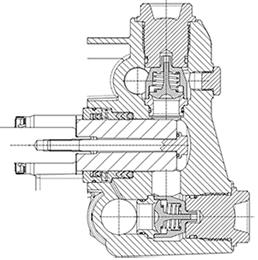

Coperchio posteriore con scarico olio.

Close

Back cover incorporated with oil drain outlet. -

More

Coperchio laterale con livello olio.

Close

Side cover incorporated with oil sight glass. -

More

Corpo pompa in alluminio pressofuso, di disegno robusto.

Close

Pump body in pressure die-cast aluminium alloy, ruggedly designed. -

More

Tappo di sfiato con asta di livello.

Close

Press-fit filler breather with dipstick. -

More

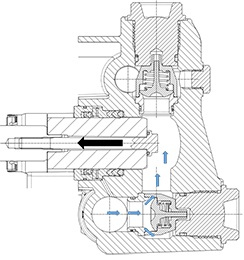

Valvole di aspirazione e mandata con passaggi acqua maggiorati.

Close

Intake and delivery valves with oversized water passages. -

More

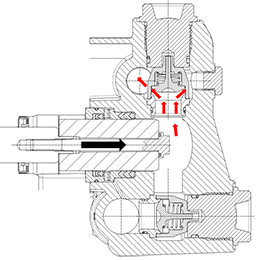

Sistema di tenuta a doppia guarnizione.

Close

Double gasket sealing system. -

More

Anelli tenuta olio con doppio labbro.

Close

Oil seal rings with double lip. -

More

Pistoni in ceramica di grosso spessore per una maggiore durata.

Close

Extra-thick ceramic pistons for greater durability. -

More

Cuscinetti a rulli conici di qualità e sovradimensionati.

Close

Top quality, oversized tapered roller bearings. -

More

Albero sovradimensionato e con terminale lungo per una migliore trasmissione della coppia, in acciaio stampato e trattato termicamente per garantire elevata resistenza meccanica.

Close

Oversized shaft with long end section for better torque transmission, in forged steel and heat treatment to ensure high mechanical resistance. -

More

Pistoni di guida sovradimensionati e rettificati per una riduzione dell’attrito durante lo scorrimento ed una migliore tenuta olio.

Close

Oversized piston guides for smoother stroke and better oil seal functioning.

Outside view

Vista esterna

See inside

Mostra interno

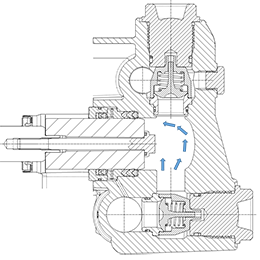

Water cycle

Ciclo acqua

Industrial cleaning

Industrial cleaning Pressure washers

Pressure washers Industrial processes

Industrial processes Car wash

Car wash Manufacturing

Manufacturing Agriculture

Agriculture Food industry

Food industry Municipality

Municipality Misting

Misting Sewer jetting

Sewer jetting Construction industries

Construction industries Marine industry

Marine industry Fire-fighting

Fire-fighting

Outside view

Vista esterna

See inside

Mostra interno

Water cycle

Ciclo acqua

Annovi Reverberi pumps general features

Outside view

Vista esterna

See inside

Mostra interno