-

More

Tappo di svuotamento per rimessaggio invernale.

Close

Drain plug to empty liquid from the circuit before winter storage. -

More

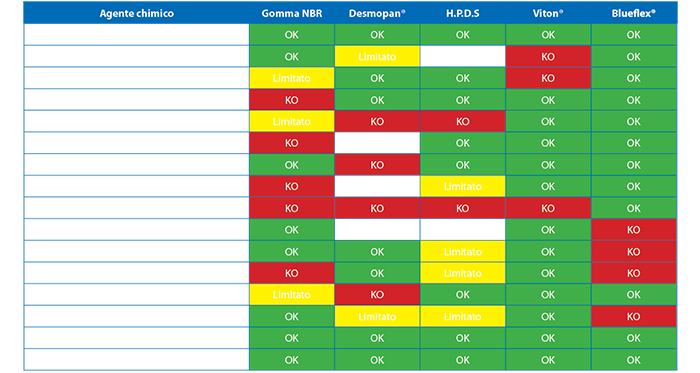

Testa in plastica rinforzata resistente ai prodotti chimici.

Close

Pump head in reinforced thermoplastic for aggressive chemicals. -

More

Robusti supporti in lamiera con trattamento di cataforesi fissati al corpo della pompa.

Close

Pump support with cataphoresis treatment on pump body. - More

-

More

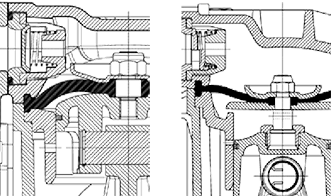

Cuscinetti a rullini di qualità sotto alle bielle per ridurre gli attriti

Close

High quality needle bearings under the connecting rods to reduce friction. -

More

Anelli di tenuta a doppio labbro

Close

Double lip oil seals. -

More

Pistoni con segmento elastico

Close

Elastic segment on pistons. -

More

Valvole di grandi dimensioni in AISI 304 (AISI 316 per la versione LFP) per un migliore rendimento idraulico e una migliore resistenza agli agenti chimici.

Close

Large valves in AISI 304 (AISI 316 for LFP version) for best hydraulic efficiency and better resistance to chemical agents.

Outside view

Vista esterna

See inside

Mostra interno

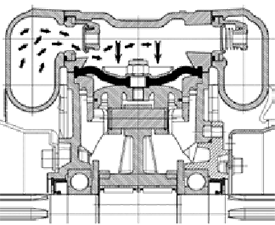

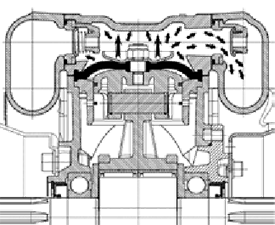

Water cycle

Ciclo acqua

Antifire

Antifire wheelbarrows

wheelbarrows Deicing

Deicing Weeding

Weeding Pest control

Pest control Liquid fertilizers

Liquid fertilizers Atomizers

Atomizers

Outside view

Vista esterna

See inside

Mostra interno

Water cycle

Ciclo acqua

Annovi Reverberi pumps general features

Outside view

Vista esterna

See inside

Mostra interno

Water cycle

Ciclo acqua

Outside view

Vista esterna

See inside

Mostra interno